OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers

OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers Detail:

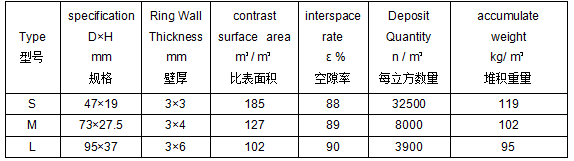

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

A Look at the Molded Gasket

OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers, The product will supply to all over the world, such as: , , ,

SEI LASER PackMaster CW

Laser flexibility for easy-open, window packaging, easy-ventilation, easy-breath in flexible packaging. System is designed for laser cutting, laser scoring, macro- and micro-perforation of single- or multi-layer flexible films.

Compatible materials include: paper, PE, PET, PP, nylon, PTFE and laminated films. Production markets for food & beverage, pet food, personal care and grocery products. Roll width of up to 1800 mm and process speed of up to 400 m/min.

It can be easily integrated into existing production lines. Very high precision in the material removal and macro/micro-perforation, repeat-ability of the process over time. Up to 400 m/min achievable in cutting, laser scoring and micro-perforation processes. The digital process enables immediate process changeover and a substantial reduction in time and costs (not possible in the case of “analogue” mechanical die cutters).

Printing, Packaging, Converting and Security RFID

European Equipment Supplier

Sold & Serviced by Matik, Inc.

Distributor in USA, Canada and Mexico

www.matik.com