Leading Manufacturer for Reinforced Flexible Graphite Gasket to Malaysia Importers

Leading Manufacturer for Reinforced Flexible Graphite Gasket to Malaysia Importers Detail:

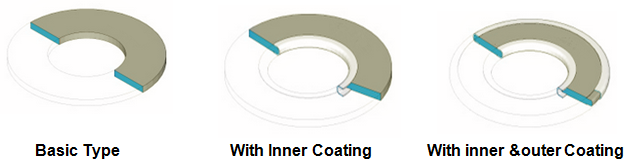

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

What Is A PTFE Ring Gasket?

Leading Manufacturer for Reinforced Flexible Graphite Gasket to Malaysia Importers, The product will supply to all over the world, such as: , , ,

A look behind the scenes at Poly Processing, manufacturers of durable polyethylene plastic storage tanks. Poly Processing is a leader in polyethylene chemical storage tanks and fittings.

Polyethylene storage tanks provide the ideal solution for storing a variety of substances. Single wall tanks can be used for water storage while high-density polyethylene (HDPE) tanks are well suited for a number of chemicals: sodium hypochlorite, sulfuric acid, hydrochloric acid, sodium hydroxide, acids, polymers, exhausts and more can all be stored. Polyethylene storage tanks feature one-piece construction to eliminate the risk of leaks developing at seams on the tank. The poly material used makes these tanks highly resistant to corrosion.

Visit Poly Processing to learn more about polyethylene tanks: https://www.polyprocessing.com/