China Gold Supplier for Reinforced Flexible Graphite Gasket to Washington Factories

China Gold Supplier for Reinforced Flexible Graphite Gasket to Washington Factories Detail:

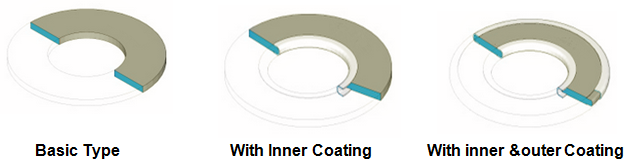

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

Comparison of O-Ring Materials

China Gold Supplier for Reinforced Flexible Graphite Gasket to Washington Factories, The product will supply to all over the world, such as: , , ,

After i got done siliconing and painting my box, I figured I’ll make a ‘How to’ video on sealing the gap between the subwoofer and the box. My total cost out of pocket to just seal the gap was less $15 after tax. But prices may vary depending on the hardware store that’s nearest to you.

There was a couple of things I forgot to mention in the video. When you you apply the weather stripping, make sure the surface area is clean and free of any dust. Second, and most important, once you have the mounting hole of the sub lined up with mounting holes, DON’T put a lot of presseure when tightening the screws. Put to much pressure and you’ll push the t-nut out of it’s place. Happened to me twice, hahaha!

So, yeah, just put enough pressure to let the screw tighten. Then once it’s tight, you can torque down the screw tight enough so it won’t come loose.

Thanks for watching my vid, and please rate.

mastagoof