New Fashion Design for Spiral Wound Gasket-RIR to Angola Manufacturers

New Fashion Design for Spiral Wound Gasket-RIR to Angola Manufacturers Detail:

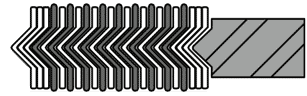

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

New Fashion Design for Spiral Wound Gasket-RIR to Angola Manufacturers, The product will supply to all over the world, such as: , , ,

Product Description:

Hart Industrial O-ring Unions are engineered to provide 3000 lb. service and are the most popular union in the industry for general purpose applications. The flat face design provides turbulence free fit across seats. This design is ideal where piping requirements dictate the necessity of having a flat face seal to make and break the pipe line. All HART Unions are made in the USA.

Standard O-Ring Union Features:

•Turbulence Free: All unions provide a turbulence-free fit across the seats

•O-Ring Isolation: The O-Ring seal is strategically located in the thread piece face eliminating O-Ring media contact and added protection against abrasives and erosion.

•Precision Machined components: All unions are precision machined to provide high quality and fail-safe leak proof reliability.

•Interchangeable End Connections: Threaded, socket weld, and butt-weld ends are interchangeable. This feature reduces overall costs by eliminating unnecessary nipples, bushings, couplings and inserts.

•Material Versatility: Unions can be provided in all standard metals or combination of metals. This includes 304 Stainless, 316 Stainless, A 105 Carbon Steel, Brass, Monel 400, Hastalloy, and Titanium.

•Excellent vibration resistance: Seals will not loosen, even under extreme pressure and pressure surges.

•No maintenance: Once initial seal is made, no further tightening required.