High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers

High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers Detail:

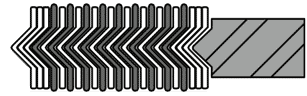

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

A Look at the Molded Gasket

High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers, The product will supply to all over the world, such as: , , ,

Learn how to weld plastics – (Plastic Fabrication – Plastic Repairs)

Welding plastics is not rocket science, but you do need the right equipment and must follow a few basic steps. Surface preparation, V’ing, Tacking, then you are ready for the main welding. Use either the pendulum welding technique, or use our speed welding nozzles for long weld runs. This video can also be purchased on DVD for viewing in a domestic DVD player.

In this video:

Plastic Welding with the Techspan RION – The hand gun for plastic welding of all different types of thermoplastic materials. Techspan Hot Air Tools can be fitted with a range of different accessory nozzle. Hot Air Hand tools are ideal for welding of roofing membranes, flooring, tarpaulins, plastic pipes and platic tanks, and much more. It is possible to weld the following materials – PVC, PP, PE, PA, PC, EVA, TPO, EPDM .. just to name a few – With Techspan hot air plastic welding is too easy !

What tool is being used? Techspan RION – The hand gun for plastic welding all different types of thermoplastic materials. Techspan Hot Air Tools are available with a full range of different kind of accessory nozzles, to meet a variety of applications. eg. Hot Air Hand tools for roofing, flooring, tarps, plastic pipes and plastic tanks, and so on.. Will weld PVC, PP, PE, PA, PC, EVA, TPO, EPDM and more..

Visit our online shop at https://www.techspanonline.com

We also provide service on all major brands: including – Techspan Bak Dohle Herz Leister https://www.techspanonline.com