One of Hottest for Reinforced Flexible Graphite Gasket for Mexico Importers

One of Hottest for Reinforced Flexible Graphite Gasket for Mexico Importers Detail:

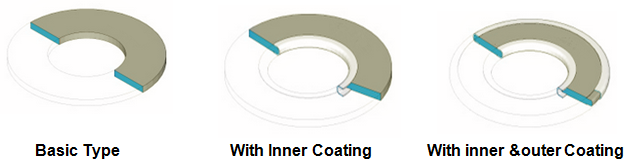

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

What Is A PTFE Ring Gasket?

One of Hottest for Reinforced Flexible Graphite Gasket for Mexico Importers, The product will supply to all over the world, such as: , , ,

Mechanical Systems’s Fully Automatic Pet Bottle Blowing Machine ,equipment is one high precision and speedy to make, bottles used for Water, Carbonated drinks, Hot fill juices, Pharmaceuticals & cosmetics , but also can used for different bottle shapes filling in one machine. With change over parts. Greatly improve the equipment usage

scope. Production capacity is from 2,000 bottles per hour to16,000 bottles per hour can be chosen by customers. Main-frame machine adopts frequency conversiontiming motor, convenient adjustment speed within throughput.

We are making 2 cavity, 4 cavity, 6 cavity Blow Machines fully auto as well as semi auto 2 cavity with auto drop feature as well.

C. Machine Features:

C.1. Stably performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheated.

C.4. High adjustability to enable the preheated to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheated with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.2 percent.

Mechanical Systems

302, HSIDC, Industrial Growth Centre, Saha

Ambala, Haryana (India)

Pin code: 133104

PH No.91-9466610761 ,9215477900, 8199944430, whatsapp/ Viber/ imo 0091-9466610761

Skype: mechsys2004

Email: mechsys2004@yahoo.com, mechsys@rediffmail.com

www.filling-machines.co.in, www.mechanicalsystems.in