Best Price for Spiral Wound Gasket-CGI Export to Nepal

Best Price for Spiral Wound Gasket-CGI Export to Nepal Detail:

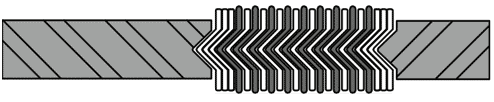

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

O-Ring Sizes for Industrial Applications

Best Price for Spiral Wound Gasket-CGI Export to Nepal, The product will supply to all over the world, such as: , , ,

Model YX-VME series how to commission vacuum emulsifier in factory cream making processing equipment que hace el equipo crema designed and manufactured by our engineer team in cosmetic&food&pharma making and packaging machinery is widely used in the daily chemical industry like cream making equipments and such like.We as a famous manufacturer moreover can design and produce the packaging machine according to the special requirements from customers.

By the strong force of high speed of homogenizer (emulsifier), the materials will go through the narrow space of the emulsifying head, it forms a powerful circulation in the vessel. In the middle part, the center blades and outer low speed anchor rotates in opposite direction. It performs great shearing, impact, and dispersion in the vessel. It will help to blend, mixer, emulsify, and homogenize the product in the vessel, and increase the stability, smoothness and luster of cream products. The emulsifying

(mixing) head is exchangeable for your various products.

The special design of high speed emulsifying head and low speed agitator & blades can achieve high efficiency of mixing & homogenizing, and the teflon scrapers of the agitator can scrape off the materials which sticked to the inner wall of vessel, and make the complete mixing at same time without corner. The teflon scraper is fixed at the outer mixing frame which will change their position by always touching the inner wall when rotating. Those scrapers can help the heat-exchange during mixing and also reduce the time of production

Features on Model YX-VME series how to commission vacuum emulsifier in factory cream making processing equipment que hace el equipo crema:

1.Mixing oil and water phases materials in high speed to get perfect emulsion product of good quality.

2. Machine consists of vacuum-resistant vessel with jacket for heating and cooling. Equipped with high speed homogenizer, scraping agitator, vacuum pump, and hydraulic pump for lifting, heating & cooling system.

3.With vacuum pump to take the air bubbles out of mixed product, and extend the time of storage.

4.The mixing shaft and emulsifying head is exchangeable, you can use the proper mixing head according to your products. There are some types for your products.

A. High viscosity type B. Low viscosity type

C. High shearing type D. Disperser type

5.Scraping unit is with moveable teflon scrapers to scrape off the materials on the tank wall and the anchor to move the materials to the center area to get better blending and mixing. The teflon scrapers are maintained manually and easily without any tool.

6.Our machines have safety devices, such us vacuum safety valve, jacket safety valve, over-loaded protection of motors, etc.

7.Our vacuum emulsifying equipment equipped with heating & cooling system which simplifies the processing. Within this same equipment, you can do from heating-melting-emulsifying-air bubble reduction(by vacuum)-cooling without changing vessels, it saves lot of labor and time for your production.

8.All contacted parts of equipments are SUS#316,the product homogenized in vacuum and close vessel can be sanitary and high quality. The specification of machine accord with the CGMP standard (CIP/SIP).

9.The measuring of raw materials, the recording of temperature for heating, melting, emulsifying, cooling, and the change of mixing speed, and the vacuum suction can be controlled automatically (PLC control).

Application:

Cosmetic Industry: Cream, Lotion, Lipstick, Shampoo

Pharmaceutical Industry: Ointment, Syrup, Injection

Food Industry: Mayonnaise, Dressing, Jam, Butter, Margarine.

Chemical Industry: Polyester, Synthetic fiber

Paint Industry: Paints, Synthetic resin paint

Others: Color, Wax, Shoe cream, Coating liquid

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about various high quality machinery like Model YX-VME series how to commission vacuum emulsifier in factory cream making processing equipment que hace el equipo crema,please email via jackdu999@yahoo.com or browse our website https://penglaichina.com.

Watch us on Youtube:https://youtube.com/user/penglaichina

Follow us on News Center:https://www.penglaichina.com/news/

Skype us by :turnanewleaf

Call us via:0086-15811882441

Whatsapp:0086-15811882441