Manufacturing Companies for Pall Ring to Albania Factories

Manufacturing Companies for Pall Ring to Albania Factories Detail:

Pall Ring has features of low pressure drop, great flux, high efficiency.

Material: Stainless steel, carbon steel, aluminum, bronze, 304L, 316L, and other alloy, carbon seep aluminium.Strengthen polypropylene, strengthen nylon6, strengthen nylon66, strengthening PBT can also be requested by user.

Application: Used in all kind of separation, absorb, dis-absorb plants, constant decompress plants, compounding ammonia plant, decarbonization plant, desulfuration plant,separation of ethylbenzene, separation of isooctane/ methylbenzene.

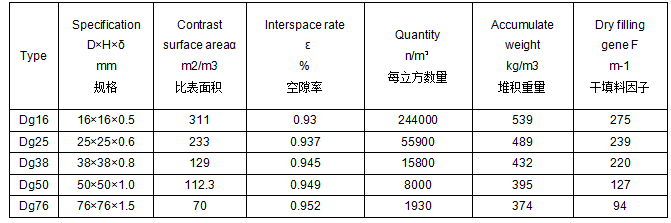

Technical Data Sheet

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

O-Ring Sizes for Industrial Applications

Manufacturing Companies for Pall Ring to Albania Factories, The product will supply to all over the world, such as: , , ,

Ring Making Machine

Model: RM-6-310

Input voltage: 220V (2-phase) or customized

Power freq.: 50Hz/60Hz

Rated power: 2KVA

Ring diameter: 90-310mm

Wire thickness: 2.5-5mm

Throughput: about 2200pcs/hour(for ring diameter 150mm)

Cooling method: natural cooling

Specially made for cage production

1.High precision: intelligent “S” shape speed curve, the encoder and the servo motor form a closed-loop wire feeding control system, secure a diameter tolerance less than 0.25mm, eventually solve the ring precision issues inherent in the traditional mechanical or hydraulic ring making machines.

2.High stability: wire feeding unit is driven by two motors directly without gears, belts or other transmission parts which would get less precise due to wear-out.

3.Easy operation: ring size is adjusted by turning the wheel, much easier than traditional mechanical or hydraulic machines.

4.User friendly UI, the counter always shows the amount of rings formed.

ZGTEK is a leading supplier of filter cage welding machines, providing a wide range of product portfolio from a stand alone machine to a whole automated line, with best-in-class flexibility, quality and cost-efficiency. The company is located in Jiaxing, which is next to Shanghai, the biggest airport and seaport of China.

Main products:

Filter cage welding machines – round/tubular cage, star cage, oval/flat cages, split cage, conical cage

Wire straightening and cutting machine

Auto ring making machine

Top and bottom cap/collar welder

Butt welding machine

Venturi tube welder

Cage welding assisting machines