OEM Supplier for Serrated Gasket to Comoros Factories

OEM Supplier for Serrated Gasket to Comoros Factories Detail:

1.Structure

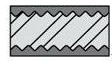

Serrated Gasket is made of machined flat metallic plate with waved or corrugated surface in 90 degree angle.

The Serrated Gasket with inner and outer rings or composite gasket attached with flexible graphite or Teflon sheet are available depending on the working location and requirement.

2.Characteristic

Serrated Gasket is an idea gasket used in low pre-tightening, the soft sealing surface avoid metal to metal touch, can be combined reliably and closely, protect flange not to be damaged. This kind of gasket is suitable to high pressure and high temperature location. Strong corrosion resistance, stable and reliable sealing function.

3.Gasket Typ

Basic Type With outer Ring

4. Working Environment

Working Temperature:~650℃

Working Pressure:6.4-16.0MP

Min. Pre-tightening:y=70MPa

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

O-Ring Sizes for Industrial Applications

OEM Supplier for Serrated Gasket to Comoros Factories, The product will supply to all over the world, such as: , , ,

Website: www.hitonsv.com Email: sales@hitonsv.com —————————————————————–…

Fully automatic toothpaste filling sealing cartoning sleeve wrapping line tube filler sealer cartoner wrapper equipment

Ointment cream lotion paste tubes filling sealing high speed equipment filler sealer machinery

Model YX-FS60-II

Voltage 220V/380v/50Hz/60Hz

Productivity 80-100pcs/min

Filling volumE 3-250 ml(customized)

Tube diameteR 11-38mm(customized)

Tube length 50-200mm(customized)

Max power 7.5KW

Water consumption 3-6L/min

Machine weight About 1300kg

Dimension(L*W*H) 2950×1300×1800mm

soap carton perfume box folding cartoning packing machine fully automatic small boxes gluing cartoner equipment

model YX-CP100

Encasing speed 30-120 case/min

Box Quality requirement 250-350g/m*m

Dimension range (L× W× H) (50-180)mm* (30-85)mm* (15-50)mm

Leaflet

Quality requirement 50-65g/m²

Unfolded leaflet specification L× W (80-300)mm*(70-210)mm

Folded leafilet specification(1-4)*(L× W) (70-210)mm*(20-40)mm

Compressed air Working pressure 0.5-0.7mpa

Air consumption 120-160L/min

Power supply 220V 50HZ

Motor power 1.5kw

Machine dimension(L× W× H) 3200mm* 1200mm* 1900mm

Machine weight 1500kg

sleeve sealing shrink packaging machinery fully automatic for bottles cans jars boxes Sleeve type thermal PE film packing equipment

model YX-SP6540

Sealing type sleeve sealing

Power supply 380V/50-60Hz/3phase

Max product size 420(L)*300(W)*320(H)mm

Max Packing capacity 20 packs per minute

Film type polyethylene (PE) film

Max film size 630 (width) *280mm(outer diameter)

Power consumption 20.5kW

Tunnel oven size 1800mm(L), entrance 600(W)*400(H)mm

Tunnel conveyor speed 15m/min

Tunnel conveyor chains with rotating silicon coated rods

Working height 800-850mm

Air pressure ≤0.5MPa(5 bar)

P L C SIEMENS S7

Sealing system permanently heated seal bar coated with Teflon

Operating interface Eview displayer

Weight 1050kg

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.

For more information about penglai packaging, please visit our website at https://penglaipacking.com

SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

Contact:Michael Peng Skype: penglaichina Email: penglaipacking@gmail.com whatsapp:+86-15012795261