Excellent quality for Spiral Wound Gasket-CGI for UAE Manufacturers

Excellent quality for Spiral Wound Gasket-CGI for UAE Manufacturers Detail:

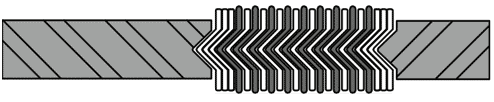

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

O-Ring Sizes for Industrial Applications

Excellent quality for Spiral Wound Gasket-CGI for UAE Manufacturers, The product will supply to all over the world, such as: , , ,

Continuous band sealer

From : Premier industrial corporation(Ahmedabad)

www.codingmachineindia.com

whatsup:+919227435005 & +919824347679

email: packseal.solutions@gmail.com

Premier industrial corporation Ahmedabad Continuous Band Sealers are industrial-grade machines designed for light-duty applications. They will seal bags made with thermoplastic materials including laminations, PE and BOPP.These versatile machines offer several adjustments which allow them to be used for a wide range of applications. Typical products being packaged with these units include Aggregates, Coffee, Chemicals, Spices, Soaps, Sauces, Snacks, Cookies, Chocolates, Cereals, Dyes, Grains, Pet Food, Pastas, Pastries, Flours, Parts, Tortillas, Vegetables, etc. These Band Sealers can be converted for horizontal or vertical operation, and include integrated embossing coders and motorized conveyors.

WE HAVE MANUFACTURE AND SUPPLIED THIS MACHINES TO VARIOUS COUNTRIES SUCH AS USA, France, Poland, Bulgaria, Saudi Arabia, Ecuador, Peru, South Africa, Egypt, Indonesia, UAE, Vietnam, Pakistan, Uganda, Philippines, Greece, Columbia, Malaysia, Nigeria, Ethiopia, Lebanon, Kenya, Kuwait, Sri Lanka, Ghana, Nepal, Ukraine, Bangladesh, Australia, Switzerland, Sudan, Russia, Yemen, Iran, Morocco, Malawi, Thailand, Tanzania, Canada, Belarus ,USA ,Cyprus ,UAE ,Republic of Congo ,Canada ,Russia ,South Africa ,Crotia ,Nepal ,OMAN ,UKRAINE ,China ,Bhutan ,Ghana ,Yugoslavia ,Nigeria ,Netherlands ,Vietnam ,Thailand ,Kenya ,Iran ,Malaysia ,Bangladesh ,Pakistan, U.A.E , SAUDI ARABIA , Monrovia , Phillipines , Spain ,Liberia , Iran ,U.S.A, Canada, Germany, Italy, Jordan, Syria, Turkey, Kuwait, Iran, Algeria, Argentina, Bangladesh, Bangkok, Indonesia, Malaysia, Vietnam, Nigeria, Ghana, Malawi, Egypt, Ukraine, Nepal, Srilanka, Bangladesh, Tibet Lusaka, Egypt, England, UAE, Bahrain, Vietnam, Iran, Poland, Tanzania, Malaysia, Nigeria, Sudan, U.K., Italy, Thailand, Span, Kenya, Lebanon, Kingdom of Saudi Arabia, Sudan, Botswana, Iraq, Thailand, Span, Mauritius, Ethopia, Congo, Zambia, Namibia, Mozambique, Uganda, Yemen, Somaliya, Oman, Jordan, Turkey, Labia, Morocco, France, Germany, Ukraine, Turkey, Greece, Kazakhstan, Russia, Uzbekistan, Malaysia, Thailand,Singapore, Philipines, Indonesia, Australlia, New Zealand, kerala, trichy, banglore, chennai, delhi, jammu, kolkata, bhubneshwar, baddi, himachal pradesh, rajasthan, pune, nashik, dhule, solan, kanpur, coimbatore, satna, nagpur, thane, wada, jaipur, udaipur, ahemdabad, ludhiyana, hyderabad, tamilnadu, indore, mysore, surat, vapi, valsad, palghar, dehradoon, uttarakhand, uttar pradesh, bihar etc

NOTE: rear shaft seal is not covered in this video – this information can be found online. If you have a deep groove worn into the shaft from this seal, you may have to install the new one in a slightly different position to contact an undamaged part of the shaft to prevent leakage from the backside of the pump.

The MB re-seal kit only includes the front cover o-ring and rear shaft seal – if your pump continues to leak from the front cover after replacement of this while operating, the internal O-rings will be leaking. With time and heat they have all gone hard and brittle now anyway.The internal o-rings have to be sourced from the aftermarket. They are not available as a spare part from MB. They want the whole pump replaced in such case.

Also note, i suggest using something like silcon o-ring grease to allow easy installation of the internal o-rings. Oil on its own may allow the rings to bind and be cut, chipped or shaved, resulting in enormous leaks.