High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers

High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers Detail:

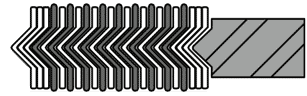

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

Comparison of O-Ring Materials

High Quality Industrial Factory Spiral Wound Gasket-RIR to Lesotho Importers, The product will supply to all over the world, such as: , , ,

Shanghai Kuko Packing Machinery Co., Ltd

Add : No.658-E, Qiangye Rd, Songjiang District, Shanghai, 201602, China

Tel : +86-(0)21-5226 5219/ 6974 6020

Fax : +86-(0)21-6221 9769

E-mail: info@goodpacking.com.cn https://en.goodpacking.com.cn

● Application: This automatic shrink wrapping machine is suitable for pop-top cans, bottles, boxes, hardware etc;

● Working process is conveying, wrapping, sealing, cutting, shrinking and cooling;

● Sealing part, the horizontal blade is vertical driving by cylinder and the blade with teflon treatment uses advanced constant temperature sealing technology. The sealing line is straight and solid, which could ensure nice sealing;

●The machine adopts the most advanced PLC programmable controller, with security and alarm devices, and the sealing system can continuously make a sealing moves smoothly without replacement, and maintenance operation is very simple;

● Stainless steel heating elements assure long life span; shrinking temperature and conveyor speed are adjustable;

● Touched screen makes the operation more easy and humanistic;

● Conveyor unit has Teflon mesh type or rod-shaped chain type for your choice;

● Intelligent digital temperature controller, air-circulation heating system;

● The packed goods are neat, compact and suitable for prolonged transport.