13 Years Manufacturer Spiral Wound Gasket-RIR for Manchester Factory

13 Years Manufacturer Spiral Wound Gasket-RIR for Manchester Factory Detail:

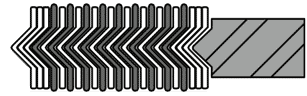

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

O-Ring Sizes for Industrial Applications

13 Years Manufacturer Spiral Wound Gasket-RIR for Manchester Factory, The product will supply to all over the world, such as: , , ,

Your Top Machine Supplier

Company: Ruian Litai Machinery CO., LTD (China)

Website: www.litai.cc

Email: litaimachine@yahoo.com.cn, trade-3@litai.cc

Skype: litaimachine

Mobile: +8615158566171

Full-automatic Plastic Cup Thermoforming Machine TQC-650B is completely automatically with material feeding, heating, stretching, in-mold cutting, rewinding into one process.

1. It is used for forming plastic sheet of PP, PS, HIPS, PVC, PET to produce various of disposable plastic products.

2. The disposable plastic products with round, square, rectangular or other shapes: plastic cups (jelly cups, coffee cups, yogurt cup, ice cream cups, cold cups, hot cups, drinking cups, beer cups), containers, dishes, bowls, trays, boxes, covers, lids, plates etc. (Please see below products samples)

* Touch Screen: Siemens, Germany.

* PLC: Siemens, Germany.

* 4 pillars (column s) to fix machine (4 post columns of pillars can be performed for better quality of finished products with different shapes (round, rectangular, oval, square shape with big sizes), highly increase the rate of finished products, and more steadily operation.)

* Feeding sheet: Controlled by Servo motor + servo drivers (YASKAWA brand, Japan)

*Servo feeding assist reduces minimizing plastic scrap, ensures feeding sheet with same accuracy.

* Plug (upper mold): Controlled by Servo motor + servo drivers (YASKAWA brand, Japan) *Servo plug assist reduces minimizing energy use on press and saving time of adjustment.

* Machine mechanism: Machine Mechanism: highly stressed parts are of very robust design, it adopts 45# steel through forged &hardened and tempered technology.

* Hydraulic pressure system of low noise and faster running.

* IR Ceramics Heaters:

Top + Bottom type

Each size IR Ceramics Heater: 60mm x 240mm

Each power IR Ceramics Heater: 650w

* Auto load for sheet roll

* Retractable, independently operated oven.

* Top + bottom larger oven size suits to form PP material with 35times/min (max.speed), no need extra preheating unit.

* Temperature control module ensures precise temperature accuracy and easy operation.

* Accessing to all digitalized functions by pressing touch screen.

* Automatic central lubrication.

* Little maintenance effort required and long intervals between maintenance.

* Most of components are from multi-national suppliers assures a reliability and worldwide compatibility.

* Machine frame made by square steel with strong quality, reliable running.

* Production capacity: For example: top dia of cup : 70mm, mold with 21cavities, the capacity is about 37800pcs/hr — 44100pcs/hr.

Technical Parameter:

Forming Area: 650mm x 320 mm

Forming Depth(Max): 130mm

Sheet thickness: 0.2mm-2.0mm

Sheet width(max): 650mm

Max. Sheet Roll of Diameter: 800mm

Forming Speed(max): ≤35 times/min

Adjustable Travel: 100mm-350mm

Oil Pump Motor: 11kw, 6grades

Plug Motor Power: 4.4kw

Feeding Motor Power: 3.0kw

Rewinding Motor Power: 0.37kw

Heating Power: 60kw

Rated Power: 80kw

Actual Power: 55kw

Compressed Air: About 0.6-0.8pa/1.6M3

Heating Type: Top + bottom

IR Ceramic Heaters

Temperature Control Module: PID, K-type

Type of Mould Multi cavity: 1-4rows

Cutting Type: In-mold cutting automatically

Water Supply: About 0.5M3/H

Overall Dimension (mm): about L6000×W2000×H2700

Weight: About 4.5T

………

More technical details with full quotation, pls contact litaimachine@yahoo.com.cn, trade-3@litai.cc

Note: Youtube is prohibited in China, we can’t read any message. Please send your information to litaimachine@yahoo.com.cn, trade-3@litai.cc, thank you.