Good User Reputation for Tellerette Packing Ring to Oslo Manufacturers

Good User Reputation for Tellerette Packing Ring to Oslo Manufacturers Detail:

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

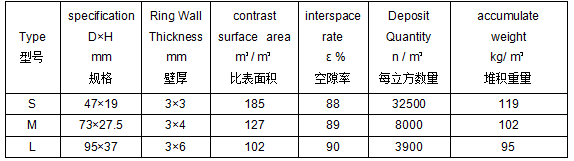

Technical Data Sheet

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

What Is A PTFE Ring Gasket?

Good User Reputation for Tellerette Packing Ring to Oslo Manufacturers, The product will supply to all over the world, such as: , , ,

KDST India is an oil seal manufacture https://kdst.in/oil-seal-manufacturers/

Call us on 0091-8851789396 (call, whatsapp)

Our Aim

We aim to minimize the possibility of generating defective products by pursuing a policy of continued technological up gradation.

Our Objective

Our objective is to achieve customer satisfaction by making available products of consistent quality through a disciplined approach to manufacturing and adherence to procedures and systems. In our pursuit of customer satisfaction, the emphasis on effecting timely deliveries at competitive prices plays an equally important role.

Quality

We believe in the quality, which is important to the reputation and success of our company. We strive to provide superior quality and performance. Stringent checks are implemented and maintained at all levels of the manufacturing process. We have established several measures to constantly match international quality standards. By using modern equipment and latest technology, we supply the products at an attractive price with unmatched quality. Our goal is to supply the products to our customers in a flawless condition to gain their trust.

Our Logistics

Our state-of-the-art manufacturing facility for Oil Seals is strategically located at Delhi, the capital of India. Our sophisticated plant and machinery to produce precision products with complete quality control. Our professionals keep abreast with the market trends and keep close cooperation with companies in the related field, which helps us in adapting to our customer needs. The company has carved out a niche for itself by providing good quality products to our numerous satisfied customers. Having the in-house facility of a complete tool room, the company is not only endeavouring for innovations and R&D, but also ensuring that new products are developed with precision and perfection.

Our Patrons

With a widespread client base spread across India, we are appreciated by our valued clients based on excellent quality and durability of the products.