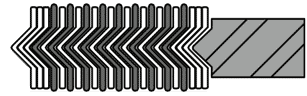

China Manufacturer for Spiral Wound Gasket-RIR Supply to India

China Manufacturer for Spiral Wound Gasket-RIR Supply to India Detail:

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

A Look at the Molded Gasket

China Manufacturer for Spiral Wound Gasket-RIR Supply to India, The product will supply to all over the world, such as: , , ,

PureServe Systems, a division of Corrosion Fluid Products Corp., is a full service distributor of sanitary and high purity fluid handling products and services for the food & beverage, dairy, pharmaceutical, biotechnology and chemical process industries.

Our extensive product lines are among the most recognized names in the industry: Alfa Laval, GEA Tuchenhagen, Top Line, Gemu, Niro Soavi, Graco, Pureflex, Newman, Rath Tubing, and Lee are just a few of the manufacturers we represent. With locations throughout the Midwest and thousands of items in inventory, you will get what you need quickly and at competitive prices.

Our Sanitary Products Include:

Process Pumps

Valves & Valve Automation

Skid-Mounted Pumping Systems

Homogenizers

Mechanical Seals & Packing

Gaskets

Fiberglass Piping & Fiberglass Grating

Silicone, PVC, Rubber & Teflon Hoses

Tubing & Fittings

Heat Exchangers

Filters & Strainers

Tanks & Process Vessels

Tank Cleaning/Spray Equipment

Protective Coatings

And more

Pure ServiceAt PureServe Systems, service is our signature. Our dedicated and experienced staff provide technical assistance as well as assembly, repair, fabrication, and installation.

Pump Repair Centers- We service all of the products we sell, as well as all manufacturers’ makes and models of pumps, valves, seals, gearboxes, mixers and heat exchangers; virtually any fluid handling equipment from any manufacturer.

Custom Fabrication- PureServe Systems is able to custom fabricate a system to your exact requirements. Our fabrication capabilities include pump carts, process skids, flow panels, custom tanks, valve clusters and more.

Field Services- PureServe Systems is able to perform many on-site services, including on-site repair, pump installation, pump and seal surveys and more.

Competence and Speed

PureServe Systems and Corrosion Fluid Products share the same motto: Competence and Speed.

What we mean by “Competence” is our knowledge and experience to recommend and apply the best equipment to your unique application requirements for maximum plant efficiency.

What we mean by “Speed” is the urgency and importance we place on responding to your questions, quotations, orders out-the-door and service when you need it.

If you are not satisfied with our service for any reason, please call our President, Joe Andronaco for resolution. We will respond quickly to satisfy your requirements.

Sincerely,

Joe Andronaco

President

Any questions,feel free to contact me.

Email:sales@chinesepacker.com Skype:zhang.tracy6

https://www.chinesepacker.com

Chick here to subscribe us

https://www.youtube.com/channel/UCo4XjYB_mRONyQKah8jbjVw

Aluminum Foil Gaskets inserting Machine Cap lining machinery

Aluminum Foil Gaskets inserting Machine

Factory Price Aluminum Foil Gaskets inserting Machine is widely used for bottle cap factory, gasket plants, pharmaceutical plants, food plants, chemical plants, packaging factory. It’s an ideal plug gasket pad equipment.

Equipment features:

1. Substitution of manual operation, automatically cramm gaskets into the bottle caps, and greatly improves the work efficiency.

2. Gasket seal reasonable speed is quick and efficient product safety and health

3. Especially suitable for the health of the requirements of the use of more demanding occasions, avoid material secondary pollution.

4. Unscrambled cover agencies additional cap function put forward, to ensure that all the material cap mouth up.

5. Transmission conveying cap, accurate positioning, the machine can be mixed and disorderly on vibration of the plate material to cap to be automatic arrangement into guide to have within wheel will cap the localization interval into glue machine plug mat location to be automatic point glue, automatically send a cap.

Main Technical Parameters:

Factory Price Aluminum Foil Gaskets inserting Machine can be customized according to the special requirements of customers.

model

DZ

specification

According to the samples customization

Production capacity

20-30pcs/min

Voltage

AC220V 50/60HZ

Power

1.0KW

Machine dimensions(MM)

1850×600×1500(L×W×H)

Weight

160KG