Factory supplied Spiral Wound Gasket-CGI to Philippines Factory

Factory supplied Spiral Wound Gasket-CGI to Philippines Factory Detail:

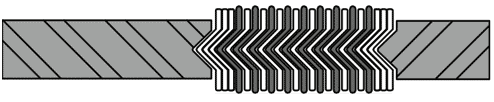

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

A Look at the Molded Gasket

Factory supplied Spiral Wound Gasket-CGI to Philippines Factory, The product will supply to all over the world, such as: , , ,

PE film Heat shrinkable machine electrical type shrink wrapping machinery

Any questions,feel free to contact me.

Email:htpmachinery@gmail.com

Skype:zhang.tracy6

More information:https://twitter.com/htpmachinery

Specifications

infrared heat shrinkable machine

1.Electronic CVT, stable and reliable

2.Frequency stepless speed, precise speed control

infrared heat shrinkable machine

Infrared shrinking machine far-infrared shrink packaging machine series: shrink film heat shrink packaging items single piece or multi-piece collection, transparent appearance items, moisture corrosion. It is widely used in the packaging of the beverage, food, pharmaceutical, electronics, tobacco, alcohol, tea, stationery, arts and crafts, plastic products, flooring, daily necessities and other industries. Suitable for PVC, PE, PP film shrinkage.

Features:

1. Far infrared direct heating.

2. Electronic CVT, stable and reliable. Frequency stepless speed, precise speed control.

3 uniquely designed automatic heating temperature control system, heat shrinkable room heating uniform and stable.

4 Teflon cross through the chain belt conveyor, heat shrinkable network marks

Custom Rolling machine can roll 20 gauge sheet metal to 50mm to 150mm diameter cylinders. This is 2 roller uses 1 large rubber roller pressed against a small mandrel. Benefits of this rolling technique are first, perfectly cylindrical finished product with no flat section near the edge unlike the conventional 3 roller machine. Removal of finished cylinder is easy because one side of the roller is automatically opens after the rolling cycle is finished.

Machine can be designed to roll tapered cylinders like motorcycle exhaust pipes, funnels and sheet metal pipe adapters.