High Efficiency Factory Spiral Wound Gasket-RIR Wholesale to Korea

High Efficiency Factory Spiral Wound Gasket-RIR Wholesale to Korea Detail:

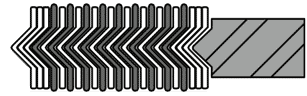

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

Comparison of O-Ring Materials

High Efficiency Factory Spiral Wound Gasket-RIR Wholesale to Korea, The product will supply to all over the world, such as: , , ,

CHECK OUT THE WEBSITE FOR THE NEW TOOL

www.icrimp.com.au

VISIT THE WEBSITE https://www.icrimp.com.au/ AND THE EBAY STORE https://stores.ebay.com.au/icrimpsystems

Worlds first copper & pex plumbing crimp press tool

The new iCrimp tool was designed to press crimp 1/2 and 3/4 copper and also 16-20-25-32 pex fittings. With 5 tons of manual crimping force in your hands you can be assured on every crimp every time. The icrimp tool weighs only 3.8kg and is capable of flame free connections to copper and pex press systems in under 5 seconds. Pressing copper eliminates the time consuming process of soldering and brazing. The icrimp press tool has constant axial pressing force, ensuring you consistent flame free connections all day long.

Key benefits

• All in one Copper and Pex hand multi-crimper

• Easy interchangeable dies, change effortlessly from different sizes and systems

• No batteries or AC power to worry about

• 360 degree head rotation for easy access

• Fully submersible tool for those wet jobs

• Press connections eliminate need for permits, oxy, torch, bottles etc

• Forged jaws press accurately without leaving burns

• Saves time and money on jobs

• Also does 18mm PB pipe

• Perfect for maintenance plumbing with all the different systems used on houses

• Sturdy and rigid construction

• 5 year product warranty

Savings $$$$

The average plumber in Australia spends approx $900 per year on GAS hire, silver solder, flux, map gas and in time/labor with brazing. Not to mention the hassle of carrying the big heavy bottles around on each job. That’s a 5 year cost of $4500. This multi-crimper cuts down your yearly costs, giving you back time and money.

Testing and Calibration

The tool has been tested to over 4000kpa on our approved pex and copper press systems so you can be confident that each join is 100% leak proof. Our multi tool is designed and engineered to be universally used and also eliminates the need to carry different tools for different systems. If you’re a 1 man plumbing business or employ multiple tradesman, you simply can’t do without the new iCrimp Press Tool. This tool will replace most of your old, heavy and expensive equipment and is at the forefront of plumbing industry technology and design.

Each tool is assembled and then individually calibrated at the iCrimp factory in Australia. We then test each tool to ensure it meets our strict quality control guidelines. This ensures that every tool that rolls out is capable of 5 ton of pressing force and is calibrated to Australian plumbing crimp fittings.

New Technology

The cutting edge technology of the iCrimp tool does away with large and expense jaws for each size piping, as used with current battery tool models. Now you simply change the inner working dies for each size tubing that you are working on. It’s that simple ! No need to spend thousands of dollars to get into the crimp market, iCrimp has designed the perfect maintenance / entry level press tool. Enjoy all the financial and business benefits this tool will do for your workplace. Save time and money on a daily basis.

More information on Copper and Pex press crimp systems

Copper

Press-connect joining of copper and copper alloy tube is fast, economical, and, most importantly, it requires no heat or open flame unlike soldering or brazing. The press-connect joining method (sometimes called press-fit) was patented in Europe in the late 1950s and continues to be used successfully there.

Press-connect joining takes advantage of copper’s excellent malleability and its proven increased strength when cold worked. The joints rely on the sealing capability of a special fitting that contains an elastomeric gasket or o-ring seal and the proper use of pressing tools and jaws. Several manufacturers offer full product lines of press-connect fittings, valves and specialty items. Our tool will crimp all watermarked copper press systems sold in Australia.

Kempress

Viega

BPress

Press Plus

and much more

Pex

PEX (or crosslinked polyethylene) is part of a water supply piping system that has several advantages over metal pipe (copper, iron, lead) or rigid plastic pipe (PVC, CPVC, ABS) systems. It is flexible, resistant to scale and chlorine, doesn’t corrode or develop pinholes, is faster to install than metal or rigid plastic, and has fewer connections and fittings.

PEX tubing is made from crosslinked HDPE (high density polyethylene) polymer.

Our tool will crimp a variety of industry standard copper ring pex crimp systems. As an added bonus, the 16mm pex die will also crimp all 18mm Poly Bute (pb) water piping. So if you come across 18mm (1/2′) Buteline or Profit in your work, you can also repair these. There is almost nothing this new tool cant do.

Some systems our tool has been tested on

Auspex

Duopex

Bush Crimp

K1

K2

Profit18

Buteline18

and much more, contact us for a complete pex system compatibility chart.

YX Series DBF1000 vertical plastic bags sealing machine with nitrogen gas filling applicable in the packaging of fragile items such as puffed food,increase automatically inflatable means on the basis of the automatic film sealing machine, packaging bag after the inflatable packaging improved crush resistance,and reduce the damage of the food during transport.

Features of band sealing machine with gas inflation system:

• Continuous film sealing machine is suitable for all kinds of bags sealing operation, has a transmission, sealing, cooling, once the functional code printing, sealing length is unlimited, high efficiency, sealing smooth and beautiful. Its compact structure, simple operation, easy maintenance, is the ideal equipment for thin-film bag sealing.

• Bags of material, whether it is solid, granules, powders, liquids, etc., can be continuous sealing machine for sealing.

• There are three ways of printing: embossing, fixed ink ribbon.

• Configure a variety of special devices according to customer requirements, such as: counting device, inflatable or suction device.

• Continuous film sealing machine is widely used in food, medicine, daily necessities, native products, chemical products, electronic products, tea, cosmetics.

Basic parameter of YX-DBF1000 Expanded food band sealer Automatic Continuous inflation Nitrogen film sealing machine حقيبة ختم الآلة:

Model YX-DBF1000

Volt 220v/50Hz

Power 750W

Sealing speed 0-12m/min

Sealing width 6-12mm

Film thickness 0.10-0.80mm

Temp range 0-300°C

Printing words no more than 39

Loading no more than 3KG

Machine size 1060×640×970mm

Weight 65kg

Tempt. Control: Intelligent temperature control device, temperature stable, and to ensure a smooth and beautiful sealing.

Speed: Configuration stepless speed control device, easy to adjust and simple.

Feed: Streamlined design, easy and accurate feed material inlet.

Equipped with a sealing tape correction device, to ensure sealing quality.

Adjustable conveyor, freely adjust according to the size of the bags, a wide range.

Conveyor Belt Adjust: Timely adjustment of the direction of the conveyor belt bags has always been at the center line of the sealing device.

Quality motor, to increase the load. Seamless PTFE sealing tape, high temperature, longer life

After-sales service on YX-DBF1000 Expanded food band sealer Automatic Continuous inflation Nitrogen film sealing machine حقيبة ختم الآلة:

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse,misapplication, storage damage,

negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install

and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After-sale service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible.The cost should be in your account.(as above).

PENGLAI INDUSTRIAL CORPORATION LIMITED

US agent Office

9284 talway cir Boynton beach. fL 33472

UK Agent Office

69 Waterloo Road Manchester England M8 8FJ

Contact: Jack Du

Cel: 0086-15811882441 0086-13077872898

Phone: 0086-20-84206097 0086-755-25423447

Fax: 0086-755—25417648

Email: jackdu999@yahoo.com

Skype: turnanewleaf

Website:

https://penglaimachines.com

https://youtube.com/user/penglaichina

https://youtube.com/user/mrjackdu007

https://youtube.com/user/cosmeticmachines