OEM China High quality Reinforced Flexible Graphite Gasket Wholesale to Netherlands

OEM China High quality Reinforced Flexible Graphite Gasket Wholesale to Netherlands Detail:

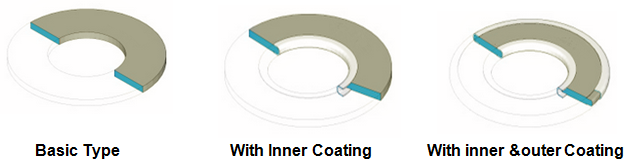

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

OEM China High quality Reinforced Flexible Graphite Gasket Wholesale to Netherlands, The product will supply to all over the world, such as: , , ,

Request a Demo: https://www.megadyne.com/samples

https://www.megadyne.com/EZClean

Discover how vital pure PTFE is to creating the performance of the E-Z Clean® electrodes. E-Z Clean non-stick electrodes feature a proprietary polytetrafluoroethylene (PTFE) coating that reduces eschar buildup during surgical procedures, enabling surgeons to use lower power settings. Lower power settings mean less thermal necrosis to surrounding tissue and a further reduction in eschar build-up.

E-Z CLEAN PTFE = FASTER SURGERY

Save time and minimize cleaning disruptions during electrosurgery by using Megadyne’s E-Z Clean non-stick tips.

MODIFIED TIP ELECTRODES

HIGHEST PRECISION AND ENHANCED SAFETY FOR CONFINED-SPACE PROCEDURES

https://www.megadyne.com/ez_products.php

Modified tip electrodes are ideal for reducing the risk of alternate site thermal injuries in procedures where space is limited.

• Only 4 mm of the distal tip is exposed thus minimizing the likelihood of alternate site thermal injuries.

• Features new modified PTFE insulation that resists splitting in temperatures beyond 700° F.

• Proprietary E-Z Clean PTFE-coated tips save time by reducing eschar build-up.

• Reduced eschar build-up enables surgeons to use lower power settings.

PROTECTIVE NOSE CONE ELECTRODES

FOR ENHANCED SAFETY IN CONFINED-SPACE AND HIGHMOISTURE PROCEDURES

https://www.megadyne.com/ez_products.php

New protective nose cone electrodes provide patient safety in procedures performed in moisture-rich areas and confined spaces by minimizing the chance of alternate site injuries.

• Protective nose cone reduces risk of inadvertent thermal burns caused by moisture-induced alternate current pathways.

• Minimizes chances of moisture wicking into the hand piece.

• Features new modified PTFE insulation that resists splitting in temperatures beyond 700° F.

• Proprietary E-Z Clean PTFE-coated tips save time by reducing eschar build-up.

E-Z Clean PTFE vs. Stainless Steel

Eschar build-up on stainless steel cautery tips increases electrical resistance, creating the need for higher power settings. But higher power settings make electrosurgery less efficient and potentially more dangerous.

• Stainless steel tips require stopping and starting during procedures to repeatedly scrape off eschar buildup with a scratch pad.

• E-Z Clean PTFE green tips only require a wipe from a damp sponge to clean, thus saving valuable surgeon time and the expense of scratch pads.

E-Z Clean PTFE vs. Silicone

• During higher-power procedures silicone has a tendency to degrade.

• Little or no coating on the edge of a silicone blade causes current to be directed to the edges—thus producing uneven coagulation and varying depths of thermal necrosis.

• E-Z Clean PTFE tips are evenly coated with high-grade PTFE to ensure consistent coagulation.

E-Z Clean PTFE vs. Economy PTFE

E-Z Clean electrodes are coated with pure PTFE, while economy PTFE tips may use filler ingredients like polyurethane (an inexpensive PTFE substitute) to reduce manufacturing cost. In functional testing, economy tips did not perform to the level of Megadyne E-Z Clean electrodes.

• Polyurethane breaks down at temperatures commonly seen in electrosurgery.

• The dangers of polyurethane flaking in the human body are unknown. PTFE has an established patient safety record proven over 25 years.

• When economy PTFE tips flake, they allow eschar buildup, which can slow surgeons down and cost time and money in the OR.

Megadyne, the exclusive manufacturer of E-Z Clean non-stick PTFE Coated Electrosurgery Tips, offers a full line of Electrosurgical Products including:

Mega Power Electrosurgical Generator

https://www.megadyne.com/megapower.php

Mega Vac Smoke Evacuation

https://www.megadyne.com/megavac.php

Mega Soft® Reusable Patient Return Electrodes

https://www.megadyne.com/megasoft.php

Electrosurgical Pencils

https://www.megadyne.com/es_pencils.php

E-Z Clean Laparoscopic Electrodes

https://www.megadyne.com/laparoscopics.php

ACE Blade Cutting System

https://www.megadyne.com/ace.php

Bipolar Forceps

https://www.megadyne.com/bipolar.php

Suction Coagulators

https://www.megadyne.com/suct_coag.php

LLETZ Loop Electrodes

https://www.megadyne.com/lletz_loop.php

Learn more about the E-Z Clean family of electrodes.

https://www.megadyne.com/ez_electrodes.php

Question or Comment? Contact Us!

https://www.megadyne.com/contact.php