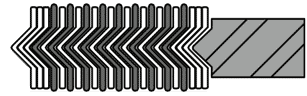

15 Years Factory wholesale Spiral Wound Gasket-RIR for Macedonia Manufacturer

15 Years Factory wholesale Spiral Wound Gasket-RIR for Macedonia Manufacturer Detail:

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

15 Years Factory wholesale Spiral Wound Gasket-RIR for Macedonia Manufacturer, The product will supply to all over the world, such as: , , ,

Carlisle is the trusted provider of energy saving construction material solutions. With it’s HVAC division and specifically the Hardcast Spray Seal sprayable duct sealant the bar has been raised for both building and contractor installation efficiency. This product is “revolutionizing the way we seal and test the ductwork” Mark Spiezio, Mid Atllantic Mechanical. Carlisle also offers the only proven, award winning solution and has the industries only issued warranty for this type of solution. The trusted provider of these products has now backed it with a 5 year warranty. Building efficiency is dependent on air tight duct work. Contractors using Spray Seal are seeing close to zero CFM leakage in the duct sections. System efficiency can be improved up to 30% with this product. Spray Seal also allows the fastest and most cost effective method of sealing for the contractor. This efficiency encourages full testing of the duct work which in turns helps to insure air tight ductwork. By using Carlisle HVAC Hardcast Spray Seal a building owner can be assured that their investment in more efficient equipment and better system controls and monitoring actually can provide what has been promised. Carlisle HVAC is part of the NYSE traded Carlisle Companies (CSL.)

GURFIL 2 KAFALI SPOOL BANTLAMA MAKINESI –

SPOOL ve PAD CALISABILME OZELLIGI

1500 R.P.M. – MIKA BANT , ALUM. FOLYO, BAKIR FOLYO, POLYESTER FILM, CAM ELYAF BANT CALISABILME OZELLIGI….