Factory supplied Spiral Wound Gasket-CGI to Philippines Factory

Factory supplied Spiral Wound Gasket-CGI to Philippines Factory Detail:

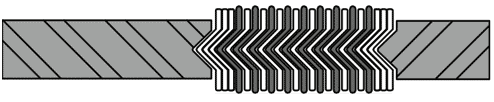

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

Comparison of O-Ring Materials

Factory supplied Spiral Wound Gasket-CGI to Philippines Factory, The product will supply to all over the world, such as: , , ,

Shanghai Kuko Packing Machinery Co., Ltd

Address: No. 4568, JiHe Road, Qingpu District, Shanghai, 201709, China

Tel: 86-(0)21-69746020 52265219

Contact : Cecilia Pii

Emai:Cecilia@goodpacking.com.cn

Mobile: +86 189 1774 9969

Application: Suits for doors, curtain frames, floors, ladders, windows, etc;(Special design for floor)

Sealing speed is up to 8meters per minute for fast and efficient production;

Easy to use, programmable computer controlled memory that reduces down time due to product changes.

Adjustable according to different sizes with simple operation.

Seal-cut is completed continuously without operator, high level of automatic, wide use.

The blade with Teflon treatment can endure high temperature without sticking;

Sealing and cutting system with constant temperature makes the sealing straight, firm and beautiful;

Banner photocell detects the product delivery accurately;

The machine applies the most advanced Siemens PLC accompanied with touch screen guarantee the precise action;

Waste film recycling system creates a clean and safe production atmosphere;

Hot air circulating shrink tunnel uses stainless steel heating elements which could ensure long life span; the shrinking temperature and conveyor speed are adjustable;

Conveyor unit of shrink tunnel has Teflon mesh type or rod-shaped chain type for your option;

All the switches are Siemens;

The machine suits for packing long products with unlimited length; high level of automation could be widely used in mass production;

The finished products are neat, compact and suitable for storage and prolonged transport.

Model GH-3015L

Power 380V 50Hz 3phase

220V 60Hz 3phase

Length of cutter 500mm

Max. packing size L (No limited) x W300 x H150mm

Packing speed 35packs/min

Machine dimension L2090xW1560xH1320mm

Air source 5.5Kg/cm3

Sealing Part

Item Name Brand Remarks

Photocell Banner From U.S.A

Solid Relay Kudom From U.K

Cylinder Festo From Germany

Solenoid Valve Festo From Germany

Reducing Motor GPG From Taiwan

Film Motor Bolong From Shanghai

PLC Siemens From Germany

Touch Screen Siemens From Germany

All Switches Siemens From Germany

Heating Elements Home-made From China

Cutter Home-made From China

Shrink Tunnel

Item Name Brand Remarks

Solid Relay Kudom From U.K

Reducing Motor GPG From Taiwan

Recycling Motor Bolong From Shanghai

Temperature Controller Omron From Japan

Frequency Inverter Schneider From France

All Switches Siemens From Germany

Insulation Aluminum Silicate 5cm thickness

Intermediate Relay Siemens From Germany