Lowest Price for IMPAC Ring to Los Angeles Factory

Lowest Price for IMPAC Ring to Los Angeles Factory Detail:

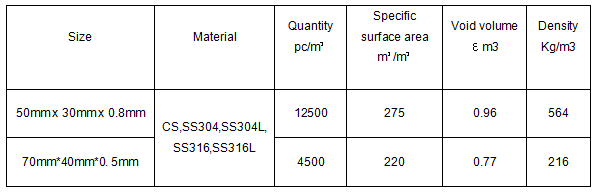

IMPAC RING is our new developed tower packing replacing Pall ring and other random tower packings. Compared with pall ring, IMPAC Ring has better compare surface area, and also can be working longer.

Material: Carbon Steel, SS304, SS304L, SS316, SS316L

Technical Data Sheet

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

Lowest Price for IMPAC Ring to Los Angeles Factory, The product will supply to all over the world, such as: , , ,

Watch as Landon Facco from Spartan Controls shows how to install a Fisher 657 Actuator onto a Fisher Sliding Stem Valve.

Spartan Controls is proud to represent several leading brands of valves and actuation technologies including Fisher Controls Valves. For more information visit us at www.spartancontrols.com.

Follow us on Twitter: @SpartanControls

Like us on Facebook: www.facebook.com/SpartanControls

Connect with us on LinkedIn: www.linkedin.com/company/spartan-controls

The images, information and materials presented in this video have been developed for general informational purposes only. The quality, accuracy or completeness of any information presented in this video is provided “as is” without warranty or condition of any kind. The information may be incomplete, and particular facts unique to your situation may render the information inapplicable or incorrect for your situation. Take all steps necessary to ascertain that information you receive is current, correct and applicable. Copyright © 2015 Spartan Controls Ltd. All rights reserved.

Following Alu rolling mill for sale

Used Aluminium Foil Mill

- Manufacturer Achenbach, Germany

- Manufacture year 1986

- Material Aluminium foil

- Entry thickness Max. 0.4 mm

- Exit thickness Min. 2*0.006 mm

- Strip width Max. 1,450 mm

Min. 800 mm

- Coil weight Max. 6,300 kg

- Spool dimension Dia. 400*1,700 mm

Dia. 279*1,245 mm

- Exit coil dia. Dia. 400/1,485 mm

- Roiling speed 0 – 800/1,500 m/min.

- Roiling force Max. 5,000 kN

- Back-up roll bearing Cylindrical roller bearing and deep groove ball bearing

- Work roll bearing Cylindrical roller bearing and taper roller bearing

- Main motor 850 kw

- Decoiler motor 85 kw * 2 sets

- Double decoiler motor 85 kw

- Recoiler motor 85 kw * 3 sets

- Thickness gauge FAG (Isotope)

- Automatic flatness control BBC (BFI)

- Drive system DC drive (BBC)

- PLC DP 800 (BBC)

- Electric power source 440 V 3 Phase 60 Hz