Reasonable price for Spiral Wound Gasket-CG to Brisbane Manufacturer

Reasonable price for Spiral Wound Gasket-CG to Brisbane Manufacturer Detail:

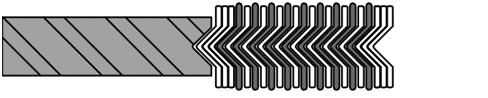

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

A Look at the Molded Gasket

Reasonable price for Spiral Wound Gasket-CG to Brisbane Manufacturer, The product will supply to all over the world, such as: , , ,

www.codingmachineindia.com

whatsup:+919227435005 & +919824347679

email: packseal.solutions@gmail.com

Pad printing system is easy and versatile machine for printing marking on various objects having even or uneven surfaces

it can even mark on curved, convex, concave surfaces easily with it super soft specially designed silicon pads.

very useful in printing auto parts, electrical components, mugs, jars, key chains, box, mobile accessories, logo printing, electronic devices, baby toys, plastic products, plastic or metal utensils, printing logo on charger, phone, helmets, calculators, caps, mouse pads, led lamps, dustbin etc it has unlimited application in all industries

the machine works on offset printing principle, its having carbon metallic plate on which the matter to be printed in itched and the ink feeding system continuously keep on inking this itched matter, the suitable shape silicon pad takes impression from this plate and leave it on the dry product surface very perfectly.

as for each impression metal plate is to be itched the machine is not suitable for frequently changing or uncertain printing matter.

the itching plate can be re-itched if needed at nominal cost.

different shape silicon pads are available to suit different printing matter size & shape of products.

USA, France, Poland, Bulgaria, Saudi Arabia, Ecuador, Peru, South Africa, Egypt, Indonesia, UAE, Vietnam, Pakistan, Uganda, Philippines, Greece, Columbia, Malaysia, Nigeria, Ethiopia, Lebanon, Kenya, Kuwait, Sri Lanka, Ghana, Nepal, Ukraine, Bangladesh, Australia, Switzerland, Sudan, Russia, Yemen, Iran, Morocco, Malawi, Thailand, Tanzania, Canada, Belarus ,USA ,Cyprus ,UAE ,Republic of Congo ,Canada ,Russia ,South Africa ,Crotia ,Nepal ,OMAN ,UKRAINE ,China ,Bhutan ,Ghana ,Yugoslavia ,Nigeria ,Netherlands ,Vietnam ,Thailand ,Kenya ,Iran ,Malaysia ,Bangladesh ,Pakistan, U.A.E , SAUDI ARABIA , Monrovia , Phillipines , Spain ,Liberia , Iran ,U.S.A, Canada, Germany, Italy, Jordan, Syria, Turkey, Kuwait, Iran, Algeria, Argentina, Bangladesh, Bangkok, Indonesia, Malaysia, Vietnam, Nigeria, Ghana, Malawi, Egypt, Ukraine, Nepal, Srilanka, Bangladesh, Tibet Lusaka, Egypt, England, UAE, Bahrain, Vietnam, Iran, Poland, Tanzania, Malaysia, Nigeria, Sudan, U.K., Italy, Thailand, Span, Kenya, Lebanon, Kingdom of Saudi Arabia, Sudan, Botswana, Iraq, Thailand, Span, Mauritius, Ethopia, Congo, Zambia, Namibia, Mozambique, Uganda, Yemen, Somaliya, Oman, Jordan, Turkey, Labia, Morocco, France, Germany, Ukraine, Turkey, Greece, Kazakhstan, Russia, Uzbekistan, Malaysia, Thailand,Singapore, Philipines, Indonesia, Australlia, New Zealand, kerala, trichy, banglore, chennai, delhi, jammu, kolkata, bhubneshwar, baddi, himachal pradesh, rajasthan, pune, nashik, dhule, solan, kanpur, coimbatore, satna, nagpur, thane, wada, jaipur, udaipur, ahemdabad, ludhiyana, hyderabad, tamilnadu, indore, mysore, surat, vapi, valsad, palghar, dehradoon, uttarakhand, uttar pradesh, bihar etc

A4000 & Wrightlon® 5200 are high temperature, fluoropolymer release films that have excellent elongation and will conform easily to the most complex curvatures.

They are capable of cure temperatures up to 500°F (260°C). These films will release from most resin systems and will provide a glossy finish when used directly on the laminate.

All standard perforations are available. Please see our perforation table in the “Release Films” film section of the catalog.

Benefits:

• Excellent elongation and strength reduces bridging in corners, avoiding scrap or rework.

• High visibility colors reduce risk of FOD and leaving film on cured parts.

• Color options help differentiate perforation styles.

• Easy release off cured parts, leaving excellent finish.

• Widths up to 160 inches (4 m) without heat seams.

For more information, please visit: www.airtechonline.com