Leading Manufacturer for Tellerette Packing Ring to Honduras Manufacturer

Leading Manufacturer for Tellerette Packing Ring to Honduras Manufacturer Detail:

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

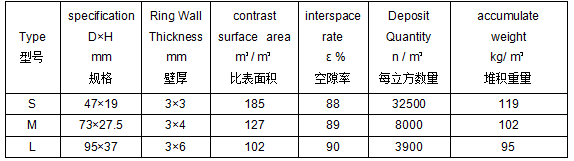

Technical Data Sheet

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

O-Ring Sizes for Industrial Applications

Leading Manufacturer for Tellerette Packing Ring to Honduras Manufacturer, The product will supply to all over the world, such as: , , ,

Three Layer Blown Film Machine

Features:

• Horizontal Oscillating Haul off with PLC control.

• Teflon Rolls, Remote control motorized open/close, up/down Bubble Cage

• Bimetallic barrel with replaceable groove section and cooling jacket

• Melt pressure, temperature probes and display Include rupture disk

• 450mm A/B/C three layer IBC Ready Die and Air Ring

• Automatic Magazine winding shaft loading , Back-to-Back Surface Winder

• with loadcell and PLC control and slitting and edge open knives.

Optional devices:

• IBC & automatic width control and Blower

• Chiller and Chill Air Box for IBC and Air Ring

• Gravimetric blender dosing system

• Yield control management system

• Thickness measurement system

• BF-A A-frame thickness measurement system

• BF-E edge thickness measurement system

• BF-S scanner thickness measurement system

• Automatic Profile thickness control Air Ring

• PIB Gear Pumps

Avita Machinery Co., Ltd.

www.avitaplas.com

service@avitaplas.com