China wholesale Spiral Wound Gasket-RIR Wholesale to European

China wholesale Spiral Wound Gasket-RIR Wholesale to European Detail:

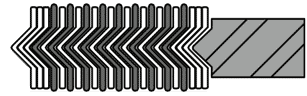

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

Useful Tips For Installing The Teflon Envelope Gasket

China wholesale Spiral Wound Gasket-RIR Wholesale to European, The product will supply to all over the world, such as: , , ,

Web: https://www.kahaninternational.com

Email: sales@kahaninternational.com

Contact : +91-8452953999

Product: https://www.kahaninternational.com/DT-58

Kahan International Offers Steam Jacketed Kettle for mango pulp processing, Model: KI-PK150

Hemispherical Double Wall Vessel with 4 legs at the bottom.

Working Capacity in kgs: As per need

Gross Capacity in kgs: As per need

Material: Mango Pulp or any paste.

Material Viscosity: As per the material to be prepared.

Inner Shell Thickness: 4 mm, MOC: SS316

Jacketed Shell Thickness: 3 m, MOC: SS304

Insulation: Can be provided as per need.

Working Pressure : 2.2 kg/cm2 or customized.

Test Pressure : 4.5 kg/cm2 or customized.

Steam Inlet: ½ inch BSP Male threads or as per need.

Condensate Drain System with Strainer, ball float steam trap, By-Pass Valve, Safety Valve, Air Vent and Pressure Gauge Attached.

3 Way approx 2-inch size Ball Valve in SS304 at the bottom for an outlet.

The machine will be resting on the adjustable bolts.

Stirrer Motor: 1 HP/2HP Bonfiglioli make, 1440 rpm

Gearbox: Bonfiglioli make with 1:100 ratio (rpm 14-15)

Anchor type blade as per the picture with Teflon scraper at the edge of the blade.

Stirrer mounted on the body of the kettle.

Tilting of the vessel can be provided if in need.

Lid provided to cover the top portion.

mango pulp | mango pulp making | mango pulp processing | steam jacketed kettle | jacketed kettle | hot mango pulp making | mango juice making | pulp making | mango pulp filling | paste kettle | jacketed paste kettle | steam jacketed paste kettle | ketchup making machine | ghee making machine | paste mixing machine | mango pulp manufacturing plant | mango pulp manufacturing