Online Exporter Tellerette Packing Ring to Indonesia Importers

Online Exporter Tellerette Packing Ring to Indonesia Importers Detail:

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

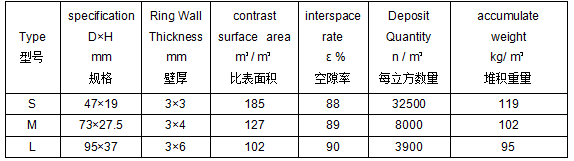

Technical Data Sheet

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

What Is A PTFE Ring Gasket?

Online Exporter Tellerette Packing Ring to Indonesia Importers, The product will supply to all over the world, such as: , , ,

Packing Machine for Grain

Very compact and versatile machine,usable for any kind of cereals. ( Rice, Polenta, semolina).Bag magazine with a capacity of 400 bags. One single filling station with volumetric dosing. Vibrating table to compact the product, trimming of the exceeding paper. Folding and closing system through hot melt. The date is printed on the top side of the bag through a stamp with dating figures of 8mm height.Capacity 1200 bags/hour. The semi-automatic collective packer can be replaced by an automatic or semi-automatic polyethylen shrinkage system. This machine is controlled by PLC. All pneumatic parts according to ISO-norm. Changing the bag size does not need more than ten minutes. Very simple handling and maintenance mark this machine.

Site: https://www.ampacking.it

Mail: info@ampacking.it