Good Wholesale Vendors Spiral Wound Gasket-CGI to Comoros Manufacturer

Good Wholesale Vendors Spiral Wound Gasket-CGI to Comoros Manufacturer Detail:

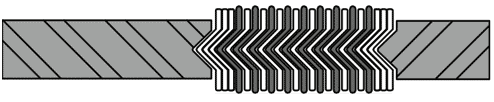

Spiral wound gasket consists of “V-shape”(or”W-shape”)metal tape and nonmetal tape, which are overlapped each other and wound continuously.To fasten the metal tape,both its start point and end point are tack welded.

Feature

Wide Scope of acceptable working conditions. Can be used under high temperature, high pressure and ultra-low temperature or vacuum conditions. Change the combination of the gasket materials is to tackle the chemical corrosion problem of diverse media toward the gasket.

Not very rigid requirements to the surface precision of the flange. May be used to seal flanges with rough surface

Easy installation and handy use.

Excellent Sealability

Products Type

Technical Data Sheet

|

Product&Type |

Size(mm) |

Temperature(℃) |

Pressure(Mpa) |

|

Spiral Wound Gasket filled with Graphite

|

φ16~φ3200 |

(In Oxidizing Environment )-240~+550℃;(In non-Oxidizing Environment)-240~+870℃ |

(Under hot water, oil etc. )30 Mpa; (Under vapor oil, gases etc.)20 Mpa |

|

Spiral Wound Gasket filled with Asbestos

|

φ16~φ3200 |

-150~+450℃ |

15 |

|

Spiral Wound Gasket filled with PTFE

|

φ16~φ3200 |

-200~+250℃ |

15 |

Application Area

The Spiral Wound Gaskets are mainly used in valves &pipes, pressure vessel, condenser, heat exchanger flanges in oil, chemical, metallurgy, vessel and mechanical industries.

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

A Look at the Molded Gasket

Good Wholesale Vendors Spiral Wound Gasket-CGI to Comoros Manufacturer, The product will supply to all over the world, such as: , , ,

WidgetWorks Hobby Vacuum Formers and Thermoform Plastic Sheets are perfect for inventors, small businesses, and DIY hobbyists who want to make custom vacuum formed plastic parts. Use our Hobby Vacuum Formers and Thermoform Plastic Sheets along with your kitchen oven and a Shop-Vac vacuum cleaner to thermoform homemade plastic parts with results that rival expensive commercial machines. Make your own plastic prototypes, clamshell and blister packaging, custom molds, scale model parts, and movie props.

Hobby Vacuum Formers and Thermoform Plastic Sheets are available through our website:

www.WidgetWorksUnlimited.com

HOW TO VACUUM FORM IN 3 EASY STEPS

STEP 1: Secure your thermoform plastic between the Hobby Vacuum Former’s metal clamping frames with the provided spring clips. Attach your Shop-Vac (not included) to the vacuum former. Place your model on top of the vacuum formers perforated aluminum platen.

STEP 2: Place the thermoform plastic in your kitchen oven and watch as it begins to sag. When the plastic becomes soft, remove it from the oven. Align the metal clamping frames with the Hobby Vacuum Former’s guides and lower the plastic over your model.

STEP 3: The hot thermoform plastic forms an air tight seal around the edges of the aluminum vacuum platen. Vacuum pressure pulls the hot plastic down around the model. After cooling for a few seconds the thermoform plastic part hardens and is ready to be removed.

Link to project page: https://www.disneyresearch.com/publication/fluid-soft-actuator/

We have developed a new method for puppeteers to remotely control mechanical characters without the use of motors. The pair of robot arms shown in this video are connected only by flexible pneumatic tubing. There are no pumps, valves, sensors, motors, or electronic controllers used. The passive connection between the two arms is made entirely by air pressure, allowing a large separation between the character and the puppeteer, and tight bends in the air control lines. The key technology is an ultra-low friction pneumatic transmission, enabled by the use of rolling diaphragm seals, instead of traditional sliding o-ring seals. If motorized, the transmission allows the motors to be placed in the body, rather than mounted to the arm, leaving the arms much lighter, and capable of faster and more graceful motion. The robot arm in this video was designed and built by Tianyao Chen, Peter Whitney, and Jessica Hodgins.