Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories

Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories Detail:

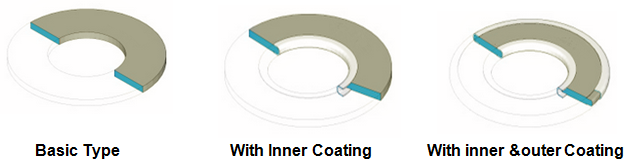

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

A Look at the Molded Gasket

Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories, The product will supply to all over the world, such as: , , ,

CHUYÊN CUNG CẤP VAN VÀ VẬT LỆU LÀM KÍN

Hotline: 0988.616.004 – 0906.095.962

Email: Vattu.leban@gmail.com – tam.leban@gmail.com

Yahoo: hoabattu027

Skype: tamkem0207

Van một chiều đồng, van một chiều kitz, van một chiều gang, van một chiều thép, van một chiều inox, van một chiều hiệu KITZ, lọc Y lắp ren, lọc y lắp bích, lọc y hiệu KITZ, lọc Y hiệu Yoshitake, lọc y của KITZ, lọc Y đồng, lọc Y bằng đồng, lọc y bằng gang, lọc Y thép, lọc Y bằng inox, lọc Y inox, lọc Y gang, lọc cặn hiệu Kitz, Van Y lọc, van lọc chữ Y…

- Van cửa KITZ(Gate Valve).

- Van cầu KITZ (Globe Valve).

- Van bi KITZ (Ball Valve).

- Van bướm KITZ(Butterfly Valve).

- Van một chiều KITZ (Check Valve: Swing, Lift, Wafer Type).

- Van điều khiển (Control Valve) bằng khí nén, điện.

- Van điện từ (Solenoid Valve).

- Van giảm áp YOSHITAKE (Pressure Reducing Valve).

- Van an toàn YOSHITAKE (Pressure Relief Valve).

- Van xả khí YOSHITAKE (Air Vent).

- Van chống búa nước (Water Hammer Arrestor).

- Bẫy hơi (Steam Trap) YOSHITAKE.

- Nối mềm (Flexible Joint).

- Nối giãn nở (Expansion Joint).

- Khớp nối cao su (Rubber Joiting)

- Vật liệu làm kín: Sheet Gasket (Jointing Sheet).

- Đầu dò gas (Gas Detector).

- Kính soi (Sight Glass).

- Gioăng tấm không aminang (non-asbestos sheeting).

- Gioăng chì (Spiral Wound Gasket).

- Dây tết chèn (Gland Packing) làm kín bơm, van, lò hơi.

- Tấm Teflon (PTFE sheeting).

- Thanh Teflon (PTFE Rod).

Shanghai Kuko Packing Machinery Co., Ltd

Add : No.658-E, Qiangye Rd , Songjiang District, Shanghai, 201602, China

Tel : +86-(0)21-5226 5219/ 6974 6020

Fax : +86-(0)21-6221 9769

E-mail: info@goodpacking.com.cn https://www.goodpacking.com.cn

GH-6030AF is one kind of side sealing packing machine. It is widely used in mass production packaging assembly line. Auto feed, transport, feed into the bag, seal, shrink all in one operation. The efficiency is high, and it fits for different sizes;

Sealing speed is up to 8 meter per minute for fast and efficient production; The blade with Teflon treatment can endure high temperature without sticking;

Sealing and cutting system with constant temperature makes the sealing straight, firm and beautiful;

Banner photocell detects the product delivery accurately;

The machine applies the advanced Siemens PLC guarantees the precise action;

Waste film recycling system creates a clean and safe production atmosphere;

Hot air circulating shrink tunnel uses stainless steel heating elements which could ensure long life span; the shrinking temperature and conveyor speed are adjustable;

All the switches are Siemens;

The finished products are neat, compact and suitable for storage and prolonged transport.